Recognizing the Significance of Welding Examination in Ensuring Structural Stability and Safety And Security Across Numerous Industries

Welding inspection is an essential procedure that safeguards architectural stability and safety and security across varied sectors. As we explore the ins and outs of welding examination, the concern occurs: what are the most vital elements that add to effective evaluation procedures?

Role of Welding Inspection

While the stability of bonded structures is extremely important to security and performance, the function of welding examination can not be overstated. Welding evaluation offers as a vital quality control procedure that ensures the adherence to developed standards and specs throughout the welding operation. By systematically evaluating welds for flaws, incongruities, and non-compliance, assessors play a crucial role in protecting the stability of frameworks throughout numerous industries.

Welding examinations incorporate an array of tasks, from pre-weld assessments to post-weld evaluations. These assessments not only determine prospective problems before they escalate but likewise enhance the overall integrity and life expectancy of welded components. Welding Inspection Milwaukee. Inspections aid to verify the skill and competencies of welders, ensuring that welding treatments are executed appropriately and products work

Moreover, an extensive evaluation method promotes conformity with regulative requirements and sector requirements, lessening the danger of catastrophic failings. By promoting a culture of safety and security and liability, welding evaluation adds dramatically to both functional and economic effectiveness. Altogether, the function of welding evaluation is important, as it underpins the top quality, safety and security, and longevity of bonded frameworks important to contemporary framework and industry.

Kinds Of Welding Inspections

Recognizing the various types of welding assessments is vital for keeping the quality and safety of bonded structures. Welding evaluations can be classified into a number of types, each offering a certain function in the evaluation procedure.

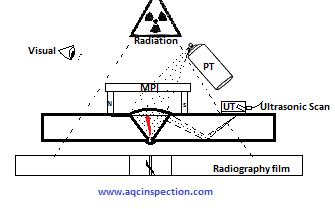

Aesthetic assessment is one of the most fundamental type, including a careful assessment of the welds with the nude eye or with magnifying. This method assists identify surface area issues such as splits, incomplete combination, or too much spatter.

These approaches enable inspectors to evaluate the integrity of welds without compromising the material's structure. Ultrasonic testing uses high-frequency sound waves to detect inner problems, while radiographic screening employs X-rays or gamma rays to visualize internal weld qualities.

Harmful screening, though less usual, includes physically examining examples to comprehend the weld's mechanical homes. Each kind of inspection contributes to a thorough evaluation, guaranteeing that welding meets sector standards and security requirements.

Industry Specifications and Laws

Establishing industry requirements and laws is vital for guaranteeing the safety and dependability of welded structures. These criteria act as standards for safety and security, quality, and efficiency, directing suppliers and inspectors in the implementation of welding procedures. Various organizations, such as the American Welding Society (AWS) and the International Company for Standardization (ISO), have actually created comprehensive standards that dictate procedures for welding methods, credentials of welders, and assessment methods.

Conformity with these laws not just boosts the high quality of welds yet also reduces risks connected with structural failings. Certain codes, such as the ASME Boiler and Pressure Vessel Code, overview demands for the construction of pressure vessels, guaranteeing they can withstand functional stress and anxieties. Additionally, local and national guidelines typically mandate adherence to these industry requirements, enhancing their significance throughout fields like building, aerospace, and auto production.

Routine updates to these standards mirror innovations in technology and welding methods, ensuring that precaution continue to be appropriate. Hence, a comprehensive understanding and implementation of these criteria is essential for welding experts, cultivating a society of security and top quality in bonded structures.

Effects of Poor Inspections

Inadequate assessments can lead to extreme repercussions in the welding market, weakening the really laws and standards created hop over to here to guarantee safety and security and structural integrity. The repercussions of poor evaluations can materialize in numerous types, from prompt security risks to long-lasting architectural failings.

Furthermore, inadequate assessments can tarnish a firm's credibility and outcome in legal effects, consisting of penalties and lawsuits. Eventually, the implications of poor evaluations extend past private tasks, influencing industry-wide criteria and public perception, hence stressing the critical demand for extensive and efficient welding evaluations.

Ideal Practices for Effective Assessments

Effective welding assessments are critical to making certain the stability and safety of welded frameworks. To attain optimal outcomes, inspectors need to comply with several ideal practices that improve the inspection process.

Second of all, examiners need to possess the required certifications and qualifications appropriate to the welding processes and materials being examined. Recurring training and expert advancement are critical to remaining updated on industry requirements and technological advancements.

In addition, making use of appropriate inspection devices and techniques, such as aesthetic assessments, ultrasonic you can find out more testing, and radiographic assessments, is vital for spotting issues that might endanger structural honesty.

Last but not least, detailed documents of the evaluation process is vital. This includes recording searchings for, photographs, and any kind of rehabilitative activities taken. Specific and clear coverage not just assists in responsibility yet likewise aids in future examinations and maintenance. By executing these finest techniques, organizations can substantially improve the performance of their welding inspections and ensure risk-free, dependable procedures.

Conclusion

In conclusion, welding evaluation is necessary for maintaining architectural honesty and safety across different markets. By systematically assessing welds and sticking to established standards, the inspection procedure minimizes risks connected with flaws and non-compliance. The execution of best methods in welding examinations not just improves the reliability and life expectancy of bonded elements however likewise supports industry guidelines. Consequently, focusing on efficient welding evaluations is important to guarantee the safety and security of employees, possessions, and general functional integrity.

As we discover the ins and outs of welding inspection, the question emerges: what are the most vital variables that contribute to efficient examination procedures?

Welding evaluation offers as an essential high quality control process that makes certain the adherence to developed standards and specifications throughout the welding Get More Information operation. In sum, the duty of welding evaluation is essential, as it underpins the quality, safety and security, and longevity of welded structures vital to modern-day facilities and market.

Different companies, such as the American Welding Society (AWS) and the International Company for Standardization (ISO), have developed extensive requirements that dictate procedures for welding methods, qualification of welders, and examination strategies.

Eventually, the implications of inadequate assessments prolong beyond individual jobs, impacting industry-wide requirements and public perception, thus stressing the important requirement for extensive and efficient welding evaluations.